Cooking has always been central to human culture, and at the heart of every cooking method lies the process of transferring heat to food. In modern kitchens, stove burners serve as the primary medium through which this transformation happens. Despite their everyday presence, many people underestimate how much the design, material, and efficiency of stove burners influence the way heat is distributed across cookware. Heat distribution not only determines the flavor and texture of food but also impacts cooking time, energy use, and even safety in the kitchen.

This article explores the role of stove burners in heat distribution, examining how various designs affect cooking outcomes, the science behind thermal transfer, and the implications for both home cooks and professional chefs.

The Science of Heat Transfer in Cooking

To understand the role of stove burners, one must first consider the physics of heat transfer. In cooking, heat can be transferred through three mechanisms: conduction, convection, and radiation. Burners primarily rely on conduction and convection. When a pan sits directly on a burner, conduction carries heat from the flame or heating element to the cookware’s base. At the same time, convection currents—whether from gas flames or the circulation of hot air around electric coils—enhance the overall spread of heat.

A stove burner’s effectiveness depends on how uniformly it transfers this heat to the surface of the cookware. Uneven heat distribution can cause hot spots, leading to burned sections of food while other parts remain undercooked. This fundamental principle makes burner design a critical factor in culinary performance.

Gas Burners and Their Heat Distribution Characteristics

Gas burners remain a popular choice in both residential and professional kitchens because of their responsiveness and visual feedback. Flames produced by gas burners wrap around the base of cookware, delivering heat not only directly but also through convection.

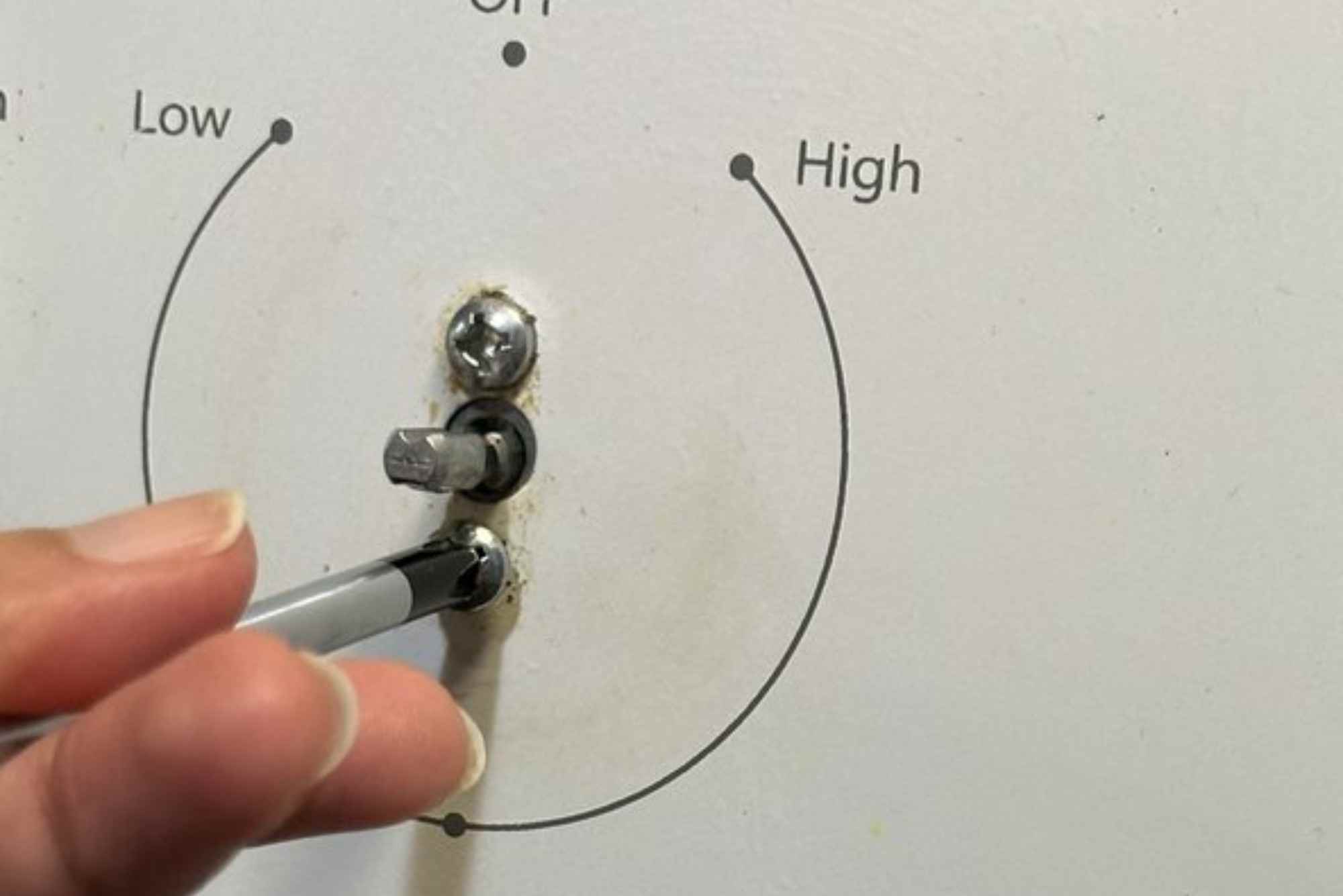

The size, shape, and number of gas ports on the burner significantly affect heat distribution. A wide, evenly spaced flame pattern ensures better coverage, while tightly concentrated flames may lead to central hot spots. Additionally, the ability to adjust flame intensity provides precise control, allowing cooks to switch from a gentle simmer to a rolling boil in seconds.

However, gas burners can also lose efficiency when heat escapes around the cookware rather than transferring directly. This inefficiency becomes especially evident with smaller pots on large burners, where flames extend beyond the base and heat the surrounding air rather than the food.

Electric Burners and Thermal Consistency

Electric burners, including coil and ceramic glass-top models, distribute heat differently than gas burners. Traditional coil burners rely on resistive heating elements that glow red as they heat cookware through conduction. They offer steady, consistent heating but can be slow to respond to adjustments in temperature.

Glass-ceramic radiant burners, meanwhile, combine conduction with radiant heat transfer. They heat cookware more evenly across the contact surface, minimizing the presence of hot spots. However, they require flat-bottomed cookware for optimal performance, since gaps reduce contact and lead to inefficiency.

Electric induction burners, a more recent innovation, revolutionize heat distribution by directly inducing electromagnetic energy into ferromagnetic cookware. This method eliminates many inefficiencies of conventional burners by ensuring that the pan itself becomes the heat source. Induction’s rapid responsiveness and uniform heating make it a preferred choice for precision cooking.

The Role of Burner Design in Uniform Cooking

Burner design plays a decisive role in how evenly heat spreads across cookware. For gas stoves, the arrangement of burner ports affects flame coverage, while the diameter of the burner must align with the size of the cookware. Oversized pans on small burners often experience uneven heating at the edges, while undersized pans on large burners waste energy and create localized hotspots.

In electric models, the heating element’s diameter, material, and wattage determine how consistently heat is transferred. Larger coils provide broader coverage, while higher wattage allows for quicker heating but may risk scorching if not regulated properly. Ceramic glass surfaces distribute heat more smoothly, but only when cookware maintains full contact with the flat surface.

Induction burners rely heavily on coil placement beneath the glass surface. Multiple smaller induction coils or advanced zoning technology can create more even heating zones, ensuring the entire pan receives consistent energy distribution. These engineering choices underscore the fact that burner design is not merely aesthetic but fundamental to thermal performance.

Cookware Compatibility and Heat Distribution

The interaction between burners and cookware is another critical factor. The best-designed burner cannot achieve uniform heat distribution without suitable cookware. The material, thickness, and shape of cookware bases influence how effectively they absorb and spread heat.

For instance, copper and aluminum cookware are prized for their high thermal conductivity, which complements burners by quickly dispersing heat across the cooking surface. Stainless steel, while durable, conducts heat less efficiently, which can lead to uneven results unless paired with an aluminum or copper core. Cast iron retains heat exceptionally well but requires more time to warm up and can magnify hot spots if the burner’s distribution is uneven.

Flat, wide-bottomed pans work best with electric and induction burners since they maximize surface contact. In contrast, gas burners can accommodate a wider range of shapes, though curved or warped bases still compromise efficiency.

Energy Efficiency and Environmental Considerations

Stove burners are not only about cooking performance; they also carry implications for energy efficiency and environmental impact. Gas burners typically waste more energy due to heat escaping around cookware, with efficiency rates hovering around 40–60%. Electric coil burners improve slightly but still lose significant energy through indirect heating.

Induction burners, however, boast efficiency levels exceeding 80–90% because they transfer energy directly into the cookware. This efficiency reduces cooking times, lowers utility costs, and minimizes heat waste in the kitchen environment. For professional kitchens where multiple burners operate simultaneously, this difference can lead to substantial energy savings.

The environmental implications extend further. Gas stoves emit carbon dioxide and nitrogen oxides, contributing to indoor air pollution and greenhouse gas emissions. Electric and induction burners, when paired with renewable energy sources, offer a more sustainable alternative for future kitchens.

Safety and User Experience in Heat Distribution

Heat distribution also intersects with kitchen safety. Uneven heating can result in accidents such as oil flare-ups, boiling over, or improperly cooked food that poses health risks. Gas burners present additional safety concerns due to open flames, which can ignite nearby flammable materials.

Electric and induction burners mitigate some of these risks. Induction, in particular, remains cool to the touch since only the cookware itself heats up. This design reduces accidental burns and enhances overall kitchen safety. Even distribution of heat across the cookware base also minimizes the likelihood of sudden hotspots that can lead to scorched food or dangerous oil splatters.

From a user experience perspective, smooth and consistent heat distribution translates to better control, predictability, and confidence in the cooking process. For professional chefs, this reliability is non-negotiable, while for home cooks, it makes everyday meal preparation more enjoyable and efficient.

Advances in Burner Technology

Recent innovations in stove burner technology highlight the importance of refining heat distribution. Manufacturers are experimenting with hybrid burners that combine gas and induction capabilities, offering cooks the best of both worlds. Smart stoves now include sensors that monitor pan temperature and adjust burner output to maintain consistent heat.

Multi-zone induction burners are another development, allowing cooks to place cookware anywhere on the surface while ensuring even energy delivery. These advances reflect a broader trend toward precision cooking, where heat distribution is no longer left to guesswork but managed by intelligent systems.

Additionally, materials science continues to push burner performance forward. Improved alloys for electric coils, refined ceramic glass for radiant burners, and advanced electromagnetic components for induction models all contribute to greater efficiency and consistency.

The Culinary Implications of Heat Distribution

At its core, cooking is about transforming raw ingredients into flavorful meals. The way burners distribute heat profoundly influences this transformation. For example, sautéing vegetables requires consistent high heat across the pan to ensure even caramelization. Baking sauces on low heat demands stable simmering without scorching. Even delicate tasks like melting chocolate depend on controlled, gentle distribution.

Professional chefs often invest in specialized burners or entire cooktops designed for specific tasks, such as wok burners with high-intensity flames or simmer burners optimized for gentle heating. In every case, the guiding principle remains the same: uniform and predictable heat distribution leads to better culinary outcomes.

Looking Ahead: The Future of Heat Distribution

As kitchens evolve, the role of stove burners in heat distribution will only grow in importance. With sustainability, precision, and safety driving innovation, future burners will likely blend intelligent design with digital controls. Artificial intelligence could one day monitor cooking progress in real time, adjusting burner intensity to maintain ideal heat distribution automatically.

Induction technology, already at the forefront of efficiency, may become the dominant standard as energy concerns and climate policies push households and restaurants toward electrification. Meanwhile, gas burners may undergo redesigns that reduce emissions and improve flame coverage to remain competitive.

Ultimately, the future of cooking lies in a deeper integration of science, design, and technology—all centered around the principle that the quality of heat distribution determines the quality of food.

Stove burners, though often overlooked, are central to the culinary process. They determine how heat is delivered, how evenly food cooks, and how efficiently energy is used. From traditional gas flames to cutting-edge induction systems, the design and function of burners shape the entire cooking experience.

Uniform heat distribution is not merely a matter of convenience; it directly affects food quality, kitchen safety, energy consumption, and environmental impact. As technology continues to advance, the humble stove burner will remain a focal point of innovation, ensuring that the simple act of cooking is refined for precision, sustainability, and excellence.