Washing machines have become an essential appliance in every modern household, making daily laundry tasks effortless. However, even the most reliable machines can experience problems, particularly with the inlet hoses that supply water to the washer. These hoses are responsible for allowing both hot and cold water to enter your machine, and when issues arise, they can lead to leaks, water pressure problems, or even complete system failure. Understanding how to troubleshoot washing machine inlet hose problems can save you from costly repairs, prevent water damage, and ensure the efficient performance of your appliance.

Understanding the Function of Washing Machine Inlet Hoses

Before you begin troubleshooting, it’s important to understand the role of inlet hoses in your washing machine. These hoses connect your home’s water supply to the appliance, usually through two separate connections — one for hot water and another for cold. When you start a wash cycle, the washing machine opens internal valves that allow water to flow through these hoses into the drum. The hoses are typically made of reinforced rubber or braided stainless steel for durability, but even the strongest materials can wear out over time due to constant water pressure, mineral buildup, and aging.

When these hoses develop issues, they may cause your washer to stop filling properly, leak from the connections, or trigger water pressure warning signals. Knowing what to look for and how to correct these problems can extend the life of your washing machine and prevent serious water damage in your laundry area.

Common Signs of Inlet Hose Problems

If your washing machine is not filling with water or you notice unusual noises or leaks, it may indicate a problem with the inlet hoses. One of the first signs is slow water flow into the drum. This could be due to clogged filters inside the hose ends, debris buildup, or mineral deposits from hard water. Another common symptom is visible water leakage around the back of the machine or near the hose connections. Over time, the hose fittings may become loose, gaskets may crack, or the hose material may weaken, leading to drips or even sudden bursts.

In some cases, you may also notice that your washing machine repair is not balancing the hot and cold water properly. For example, a cycle that requires warm water might not mix the two sources correctly due to a blocked or kinked inlet hose. Additionally, if you hear a loud hammering sound when the water fills, it might indicate that the water pressure in the hoses is too high, creating a condition known as water hammer, which can eventually damage the hose and the machine’s internal valves.

Inspecting and Diagnosing Inlet Hose Issues

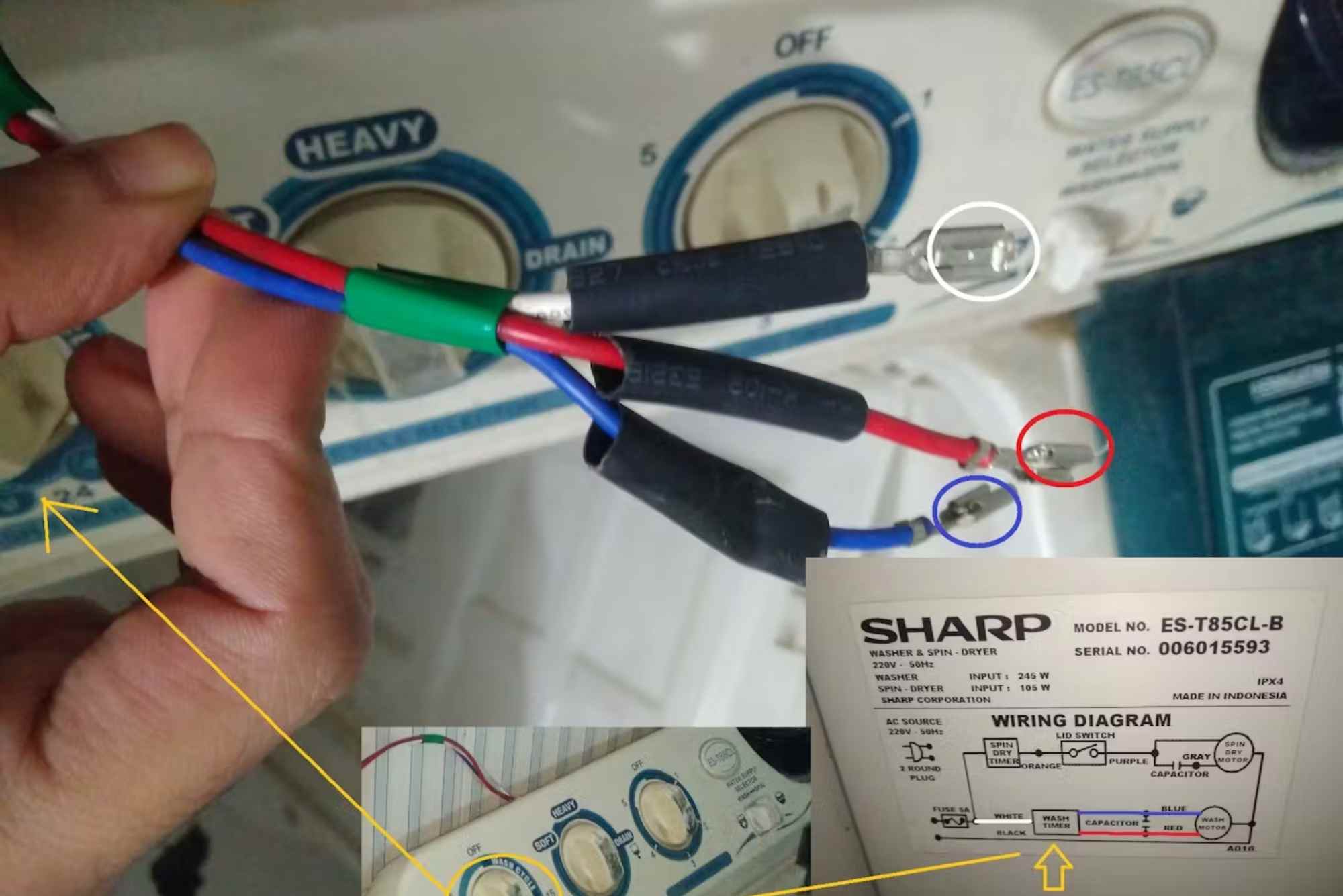

To troubleshoot washing machine inlet hoses effectively, start with a visual inspection. Unplug the appliance and turn off the water supply before proceeding. Pull the washing machine slightly away from the wall to gain access to the hoses. Check for visible cracks, bulges, or worn-out areas along the hose length. If the hose looks swollen or discolored, it’s a clear indication that it needs to be replaced immediately to prevent a potential burst.

Next, examine the connections at both ends — the faucet side and the washer inlet side. Make sure the fittings are secure but not overtightened, as excessive force can damage the threads or the rubber gasket inside the coupling. Remove the hoses carefully and inspect the small mesh filters located inside the hose ends. These filters trap sediment and debris from the water supply, but over time they can clog and restrict water flow. Clean them gently with a soft brush or rinse them under running water to remove any buildup.

If water flow is still restricted after cleaning the filters, the issue might be with the internal valve of the washing machine or the water supply pressure itself. In such cases, you might need a professional technician to perform a detailed diagnosis.

Understanding Causes of Inlet Hose Leaks

One of the most common inlet hose problems is leaking water, and there can be multiple causes behind it. Aging hoses are often the culprit; rubber hoses, in particular, tend to weaken over time, making them prone to cracks and leaks. Excessive water pressure can also stress the hose walls, leading to bursts or slow leaks at the fittings. Loose connections are another frequent issue, especially if the hoses were not installed correctly or have shifted due to machine vibrations.

Additionally, hard water can accelerate wear and tear by causing mineral buildup inside the hose or around the gasket seals. This buildup prevents proper sealing, allowing water to escape from the joints. In some instances, leaks may appear due to tiny punctures caused by pests or sharp objects near the back of the washing machine. Regular maintenance and inspection of the hoses can prevent these issues before they become severe.

Preventing Inlet Hose Failures

Preventive maintenance plays a crucial role in keeping your washing machine inlet hoses in good condition. It is recommended to inspect the hoses at least once every six months and replace them every three to five years, even if they appear to be in good shape. Using high-quality braided stainless-steel hoses instead of rubber ones can significantly reduce the risk of leaks or bursts because they offer greater durability and pressure resistance.

Always ensure that there are no tight bends or kinks in the hoses when positioning your washing machine. A kinked hose restricts water flow and puts unnecessary stress on the material, which can eventually lead to cracking. When reinstalling hoses, avoid overtightening the connections; snug fittings are enough to prevent leaks without damaging the threads or washers.

Installing water hammer arrestors is another useful preventive measure, especially if your home’s plumbing system experiences high water pressure. These devices absorb the shock caused by sudden water flow changes, protecting both the hoses and the internal components of the washing machine. Also, consider installing a shut-off valve system that automatically stops water flow if a hose bursts, providing additional protection against flooding.

Fixing Common Inlet Hose Problems

If you’ve identified the source of the issue, fixing inlet hose problems is often straightforward. For minor leaks around the fittings, replacing the rubber washers inside the hose ends can restore a tight seal. If the hose itself is damaged or old, it’s best to replace it entirely rather than attempting to patch it up. Always use hoses of the correct length to prevent excessive tension between the washing machine and the wall connections.

When reconnecting the hoses, hand-tighten them first and then use pliers to give a gentle quarter turn to ensure they’re secure. Once everything is reconnected, slowly turn on the water supply and check for leaks. Run a short cycle to confirm that the washing machine fills properly and maintains consistent water flow. If problems persist even after hose replacement, the issue might be internal, such as a malfunctioning water inlet valve that regulates flow into the machine.

Importance of Professional Assistance

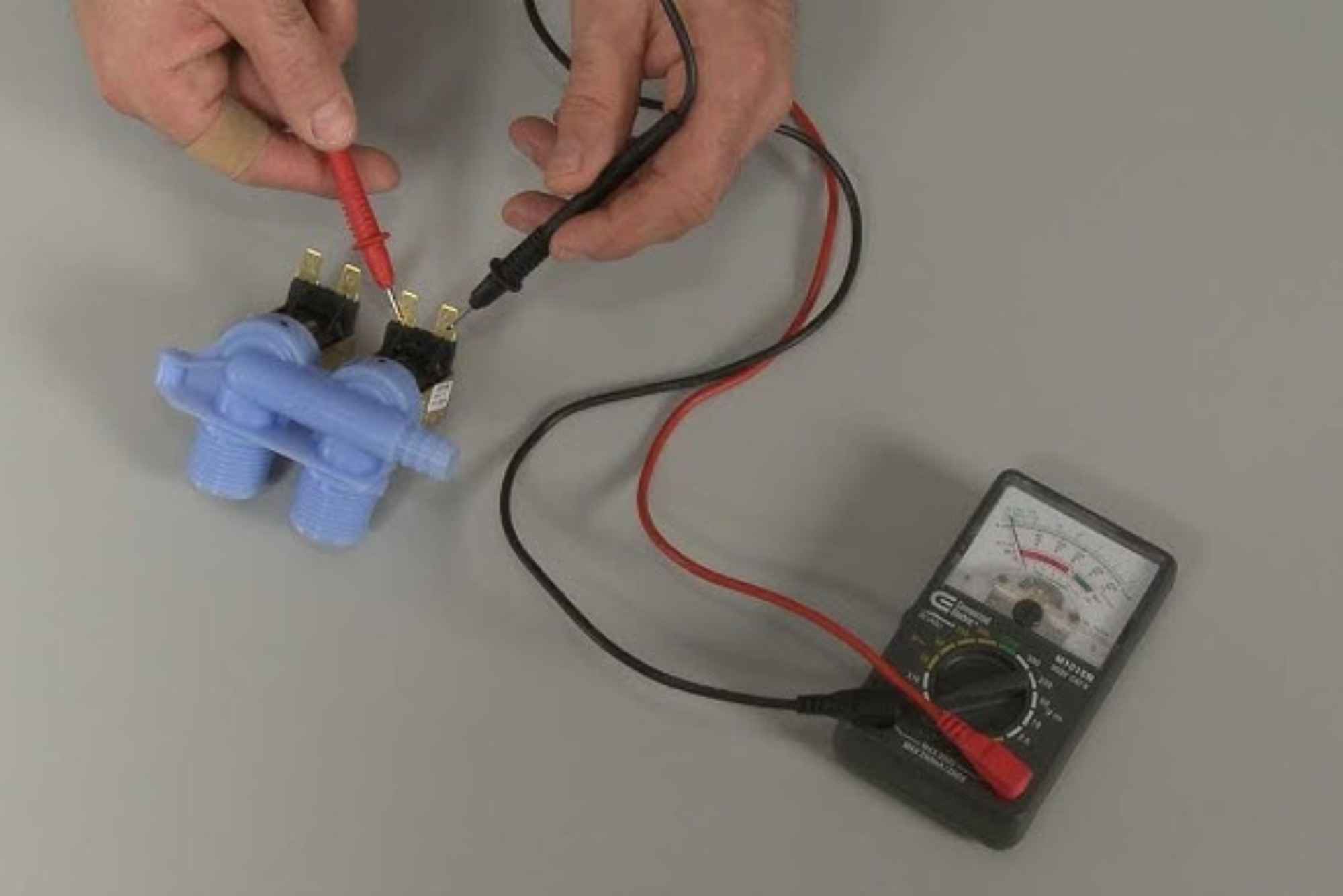

While basic troubleshooting and maintenance can be performed at home, some situations require expert intervention. If you notice persistent leaks, inconsistent water filling, or water supply issues despite cleaning and replacing the hoses, it’s time to contact a professional technician. Certified repair experts can test the inlet valve solenoids, check the water pressure, and identify hidden issues within the machine’s plumbing connections.

Hiring a professional not only ensures safety but also saves time and money by preventing recurring issues. For example, at Home Appliances Repair, skilled technicians specialize in diagnosing and repairing washing machine problems efficiently. Whether it’s a hose replacement, valve repair, or full inspection of your appliance, professional service ensures that your washing machine continues to perform optimally for years to come.

Extending the Lifespan of Your Washing Machine

Maintaining the inlet hoses is one of the simplest ways to extend the life of your washing machine. Consistent water flow, leak-free connections, and proper pressure levels all contribute to efficient washing cycles and energy savings. In addition to regular hose inspections, you should also clean the filters, check the drum seals, and ensure that your water supply pressure is within the recommended range. Avoid overloading the washing machine, as it causes unnecessary vibration and strain on hoses and fittings.

A well-maintained washing machine not only cleans clothes better but also consumes less water and electricity. Replacing worn hoses before they fail can prevent extensive water damage to floors, walls, and other appliances nearby. By investing a little time in preventive care and timely troubleshooting, you can keep your washing machine in excellent working condition and avoid costly emergencies.

Troubleshooting washing machine inlet hoses is a vital part of appliance maintenance that every homeowner should understand. From identifying early signs of wear to cleaning filters and replacing damaged hoses, each step helps prevent leaks, maintain water efficiency, and ensure long-term reliability. Neglecting these small but crucial components can lead to significant water damage or machine failure. By combining regular inspections, preventive maintenance, and professional assistance when needed, you can keep your washing machine performing at its best for many years.